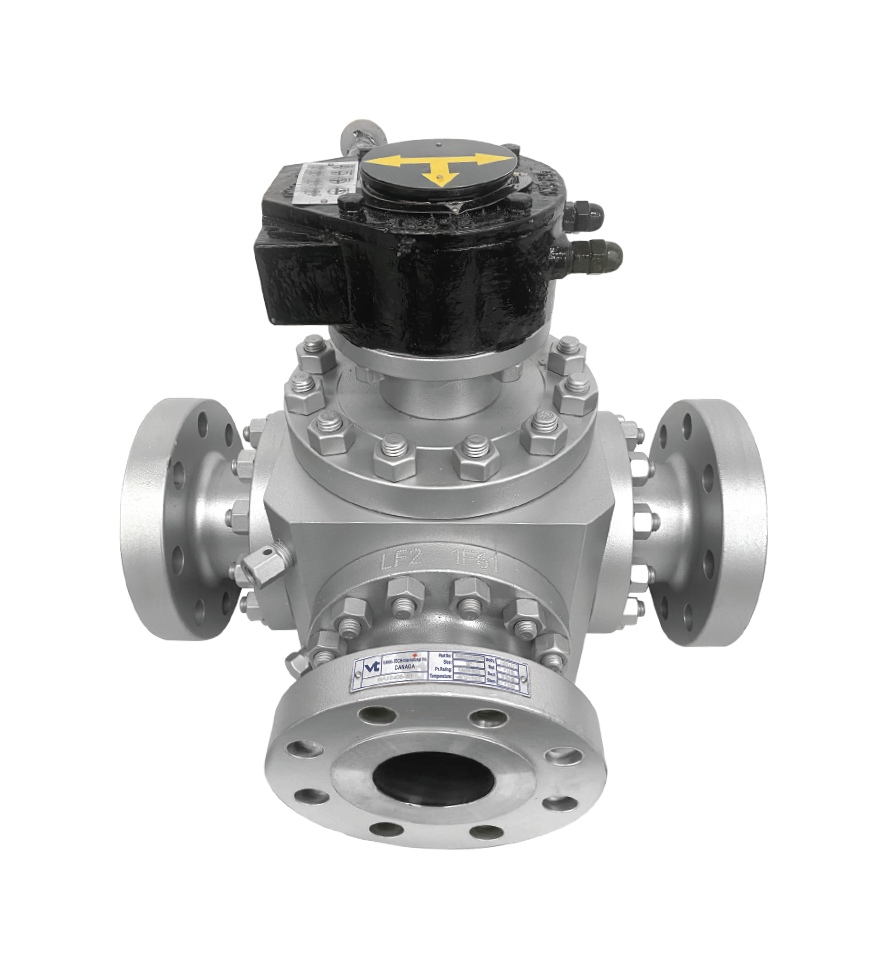

Three-way Ball Valve

SPECIFICATIONS

| Design Standard | : | API 6D / API 608 / BS 5351 |

| Size Range | : | 2” – 24” |

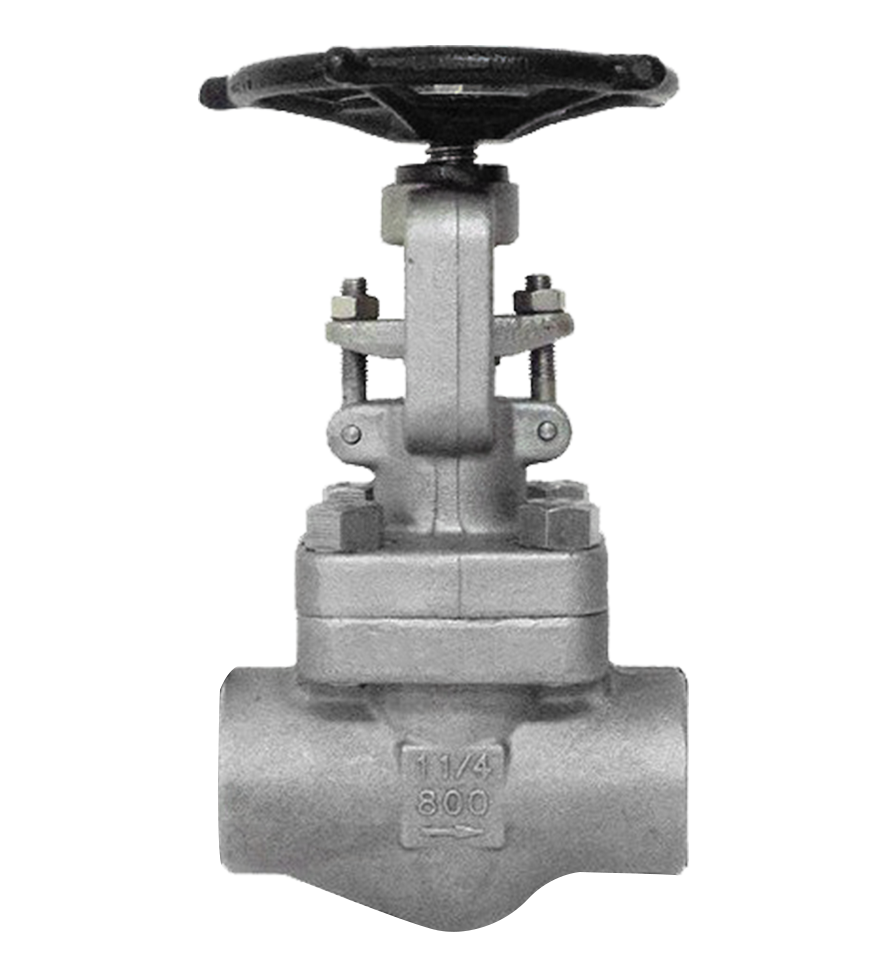

| Pressure Rating | : | Cast Body (Floating Ball): Class 150 - 300 Forged Body (Trunnion Ball): Class 150 - 2500 |

| Working Temperature | : | -46˚C to 220˚C -50˚F ~ +428˚F |

| End Connection | : | ASME B16.5 / ASME B16.47 |

| Face-to-Face | : | ASME B16.34 / ASME B16.10 |

| Test & Inspection | : | API 598 / API 6D |

Features

Three-way ball valves are used to switch over, mix and divide the flow of corrosive or non-corrosive liquid, steam or gas media. VAHN-TECH three-way ball valves are durable, versatile and cost-effective use in Chemical, Oil & Gas, Desalination or LNG application. Upon opening and closing, the smooth flow channel reduces the pressure loss. There are five choices of flow directon (1 for L-shaped and 4 for T-shaped) to meet each specific applications. VAHN-TECH three-way valves are easy to maintain, reducing the overall cost of operation. VAHN-TECH offers 2 design for 3-way valves: Floating ball design with cast body and Trunnion ball design with forged body. Forged body design is ideal for higher pressure operation, abrasive and corrosive media.

Characteristics

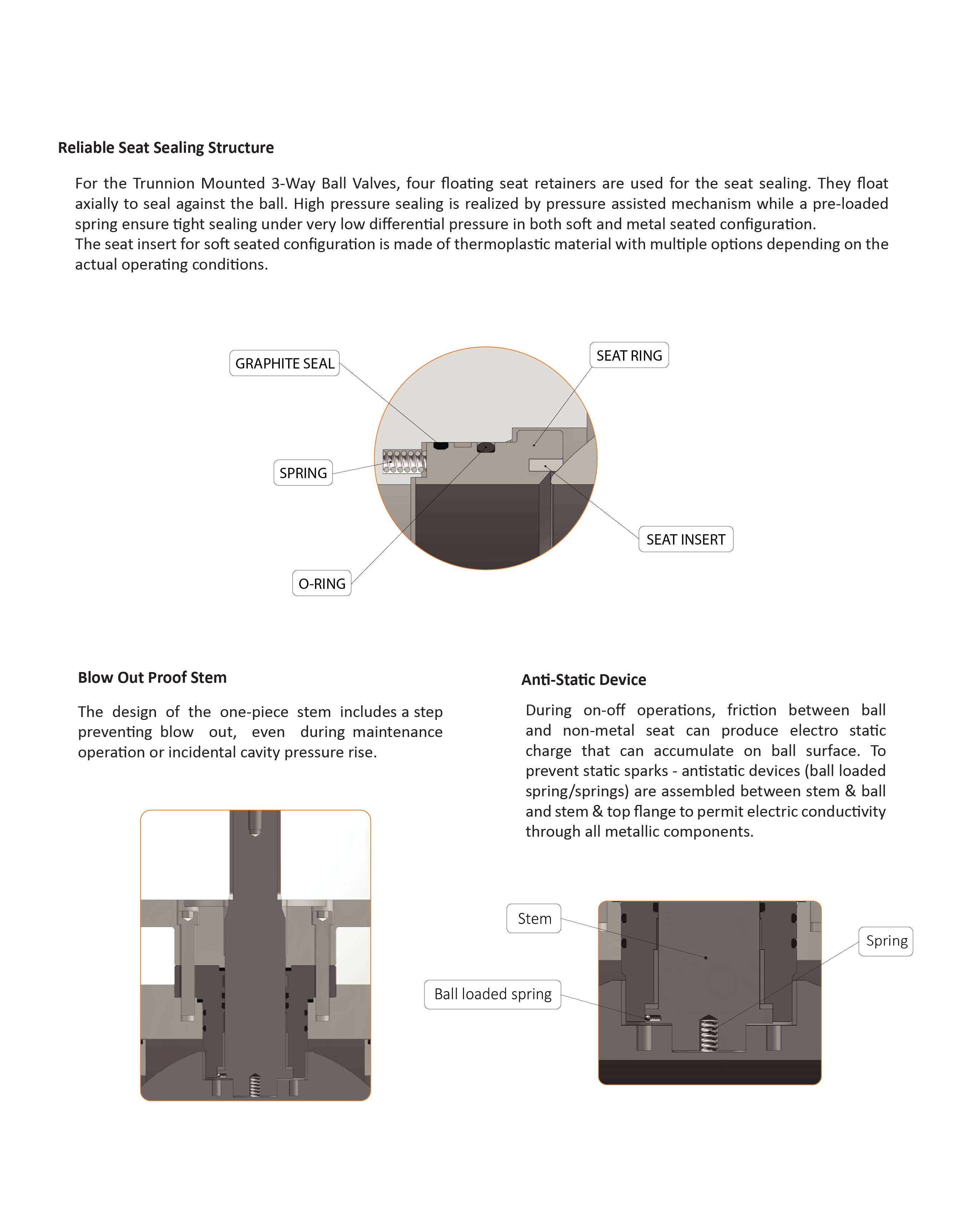

Valve seat can be designed into four-side seated floating ball and fixed ball, with smooth fluid state and reliable seal;

Valve seat can be designed into four-side seated floating ball and fixed ball, with smooth fluid state and reliable seal;

Anti-blow out stem design;

Anti-blow out stem design;

Anti-static design;

Anti-static design;

Two position locking mechanism.

Two position locking mechanism.

| Document | Type | Download |

|---|---|---|

| VT - Three-Way Ball Valves.pdf | English |